8 min read

Why Geofences are Essential for Fleet Management

By: Elizabeth Sholes on Nov 15, 2021 9:00:00 AM

If you’re a fleet manager, or you’re responsible for fleet management at your company, then you want every means available to help you do your job more efficiently. Geofences are one of those tools.

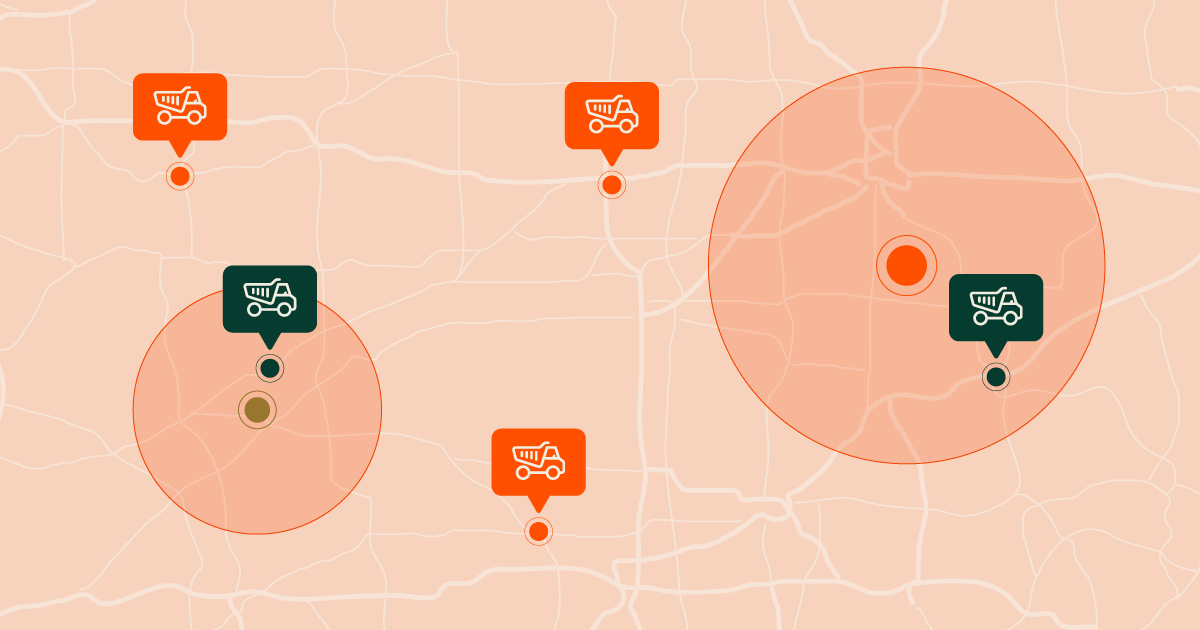

Geofencing is a location-based technology that uses GPS, Wi-Fi, Radio Frequency Identification (RFID) or cellular data to trigger a predefined action when a mobile device crosses a virtual perimeter. The designated geographic area “enclosed” by the geofence can be as small as a single property or as large as a country. Geofencing plays an essential role in effective fleet management.

In trucking fleet management language, a geofence is an invisible boundary you set up around a plant, quarry, jobsite or yard. The purpose of setting up a geofence is to track your vehicles and get information. This information helps streamline fleet management, supports fleet managers, and can improve fleet performance. When a driver’s mobile device enters or exits the geofenced area, it sets off an action.

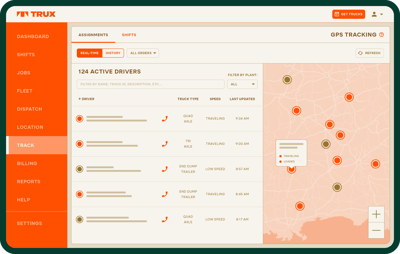

Two of the most useful actions as far as fleet management is concerned are to send alerts or collect data. If you’re already using some sort of digital solution or fleet management software to track your vehicles, geofences are a great way to leverage that technology by giving it guideposts to point out the areas where you want to capture data or receive a notification.

There are different types of geofences: circular or radius-based geofences allow the user to start at a pinpointed location and decide how far out from the center the boundary will lie; polygonal geofences allow the user to select a number of points around an area and then draw a boundary by connecting the dots; and latitude and longitude geofences which are basically a square or rectangular area set by choosing specific latitude and longitude coordinates.

In this article we’ll go into the reasons why it’s a smart move to have geofences included in your fleet management software and go over some of the best ways to use this powerful technology, which is quickly growing in popularity because of its usefulness. The best fleet management software will certainly have geofencing capabilities.

Why Bother With Geofences for Fleet Management?

In the course of your busy day, it might seem like adding yet another task to your schedule is something you don’t even want to think about. But you probably had the same reservations before you started using other digital fleet management solutions. And now you wouldn’t dream of going back to the “good old days” when you had very little visibility into your vehicle location.

Knowing the location of your vehicles is good, but when you pair that knowledge with the valuable information geofences can give you, it can take your efficiency and productivity to the next level. The data collected from geofences through your fleet management software can help streamline workflows, support day to day operations, improve customer service, control costs, improve asset tracking, and enhance driver safety.

First, let’s look at the data piece. The performance data you get from geofencing gives you both detailed and big-picture perspectives helpful in making informed business decisions and understanding ROI of your fleet activities.

You can identify delays at specific points in the delivery cycle. Analyzing your geofence data along with other variables such as the weather, season, days of the week and the material hauled will reveal important trends and help you manage them. You can then use these insights to make smarter scheduling decisions that will improve cycle times.

Here’s some of the useful data you can pull from geofences:

Cycle time

By setting up a geofence around your start location for each vehicle and another around the end, you’ll have data focused on travel times. This allows you to identify if delays are due to too much time in transit and determine what actions to take.

Maybe the answer lies in rerouting drivers around heavily congested areas. Or if delays are preventing you from keeping a project on schedule, the solution might be to add more drivers to the job. Without accurate trip data, your ability as a company to make immediate, effective changes is handicapped, and so is your effective fleet management.

Load and unload time

Like travel times, the time it takes to load and unload a dump truck can cause unnecessary and costly delays for your fleet. A geofence set up around the loading and unloading zones gives you specific insight into those components of the delivery cycle. If time loading and unloading a vehicle is contributing to delays, it will take a completely different fix than rerouting your fleet or adding trucks. But you wouldn’t know which part of the cycle to improve upon without the right geofences in place to support your fleet management.

Waiting in line

Again, another geofence set to capture this data about your fleet can tell you if your trucks are wasting time and fuel by idling too long in line. If this is the case, the situation can be remedied by having your dispatcher stagger arrival times for your fleet.

Comparisons of active job sites

It’s likely happened more than once when you’ve had several projects going at the same time, and at least one construction project is having trouble staying on track with few to no delays.

You wished you had the time and ability to observe and learn from your fleet about what’s going on at that site to make it function so efficiently. Geofencing gives you a deeper view into the logistics on-site which can help with fleet management for your company. With the data collected from all your active job sites, you can compare specific metrics and then make impactful adjustments to support your fleet management.

Comparison of multiple plant or quarry locations

The same strategy can be used to determine which plants or quarries are operating with the fewest number of delays. When comparing different locations within a given region, it’s important to make sure you have comparable geofences set up at each site so you can accurately track your fleet. If you monitor entrance and exit points at one plant and only loading times at another, you won’t have the right data to make a useful analysis.

In addition to identifying delays, geofences that are part of fleet management solutions can help you provide improved customer service. Earlier we mentioned that one of the actions you can set for triggering by your geofences is sending a notification (in-app alert, text messages, or emails). Those alerts don’t have to be limited to internal use. Notifications about a truck’s progress and updates on its delivery status can be sent to your customers. Keeping customers in the loop results in an elevated customer experience, and a better fleet management experience.

Fleet Management Best Practices Around Geofences

Although setting up geofences is not all that difficult, it is important for a fleet manager to take the time to carefully consider exactly where you’re setting the virtual boundaries for vehicle tracking. The actual boundary line is as critical to getting useful data as the area that the geofence defines. Incorrect geofences for each job can have huge implications for fleet managers, drivers, customers, your company operating costs, and overall fleet management.

If the boundaries are set up correctly, they will give you an accurate indication of when your trucks and drivers arrive on site, whether that’s a jobsite, plant or quarry. If the boundaries are off a bit you may miss critical data that could reveal where delays or bottlenecks are occurring for your fleets. Or you may even capture unnecessary data that will end up skewing your overall view on your fleet management operations.

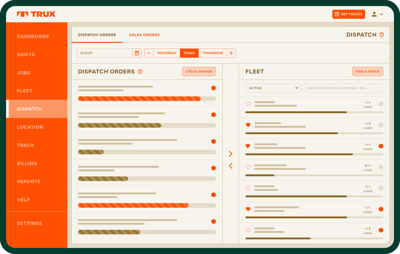

Here are some best practices to follow when you use geofencing as part of the Trux fleet management solutions. (Note: Trux uses the standard circle geofence because it’s faster to set up with accurate information.)

Capture the whole worksite.

You may think it’s a good idea to put a geofence only around the scale at a quarry. But it’s not. Here’s why. If a truck goes deeper into a quarry, it could get marked as an exit. As a fleet manager, you need to set your circle wide enough to include all the areas drivers possibly would travel to. And don’t worry if the center of your geofence isn’t in the middle of the quarry or jobsite. It’s the boundary lines that are more important for vehicle tracking.

Switch to satellite view.

Although mapview provides a quick, easy-to-understand picture for vehicle tracking, it’s better to switch to satellite view for more detail on access roads and load and unload sites. Satellite view means you can make adjustments to your geofence that are more precise and enable more accurate vehicle tracking.

Be careful about where trucks are waiting.

If you set your geofence where trucks turn to enter or exit the site, your vehicle tracking systems may pick them up as entering and exiting repeatedly. Try to place your geofence where the driver will cross the boundary at 5 mph or faster.

Don’t include nearby roads.

When you’re drawing your geofence, make sure you exclude any roads that intersect with a boundary associated with another part of a hauler’s route. This could get entered as an additional entry. Preventing these “accidental” entries and exits will keep your data accurate.

Check and check again.

It takes a bit of practice to set geofences right. Even after you’ve mastered it, it’s important to double-check the boundaries after a couple of shifts. A little tweak could get you better results.

Geofences as Part of a Fleet Management & Logistics Solution

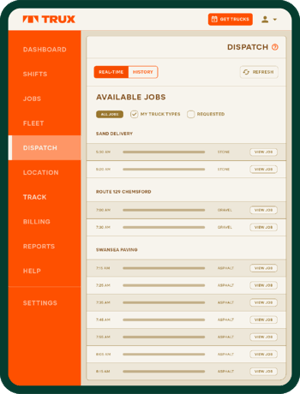

Managing dump trucks and ever-changing schedules can get overwhelming, but Trux ensures your dump trucks stay connected with our fleet management solutions. In the last year alone, Trux helped over 12,000 companies manage their dump truck logistics, facilitating more than 3.5 million loads across the U.S., with more than 28,000 technology-enabled dump truck drivers in our network.

Trux’s management system gives fleet owners the tools to:

-

Schedule and Dispatch

-

Reduce Back Office Burden

-

Improve Visibility

-

Access More Work

Conclusion

Using geofences as a strategy in your fleet management is smart for many reasons. It allows you to capture helpful data to identify where delays are occurring--whether in transit or during load/unload. You can learn if and where your trucks and drivers are waiting in line too long. It also allows you to compare the performance of different job sites, plants or quarries, as well as driver behavior. You are then able to make adjustments for fleet management based on reliable data rather than gut feelings or guesswork.

Another benefit to using geofences in your fleet management software is improved customer service. By having alerts sent to your customers, you can enhance their experience and set yourself apart from the competition.

If you’re interested in learning more about how geofences can help your fleet management, and how fleet management software can help, why not give Trux a call? Our logistics experts are ready to answer any fleet management questions about this exciting technology or any other part of dump truck logistics.

Related Posts

What is Goefencing in Fleet Management? Best Practices

First, let’s talk about what a geofence is. A geofence is a virtual boundary, set up around a...

Dump Truck Cycle Time Calculator to Help Make Decisions

As you may already know, or read in our article “Geofences: What Are They & Why Should You Care?”,...

Construction GPS Tracking and Tracker for Equipment | Trux

If your business owns construction equipment, you have likely gotten calls from reps trying to sell...